Coordinated disposal of fly as…

Suzhou JoyFa Environmental Technology Corp. Ltd.

National Hotline: 0512-68653260

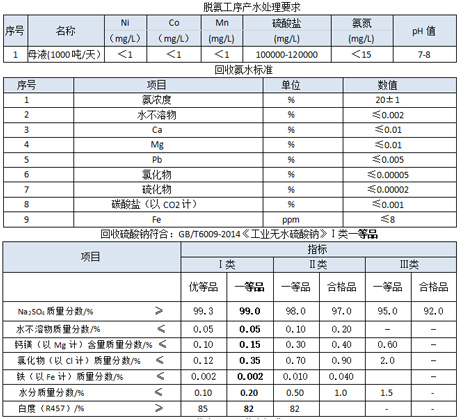

Project name: Lithium industry resource recycling

Customer Unit: Jiangsu Dangsheng Material Technology Co., LTD

Scheme design: 41t/h MVR evaporation crystallization system