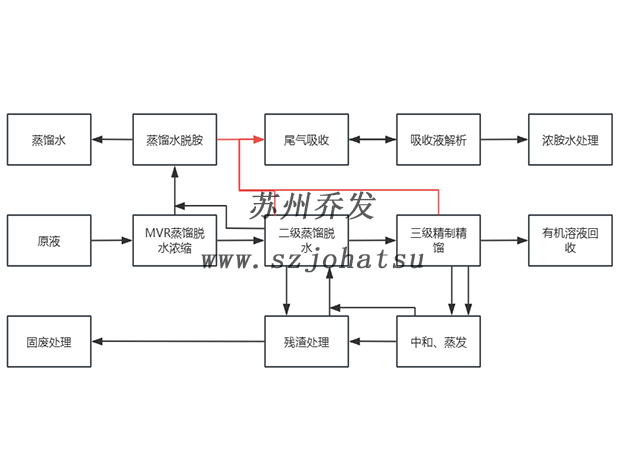

Triple effect sodium chloride evaporator

It is composed of various heating evaporators, separators, condensers, hot pressure pumps, vacuum systems, liquid transfer pumps, condensate drainage pumps, operating platforms, electrical and instrument control cabinets, valves, pipelines and other systems.

MORE>>