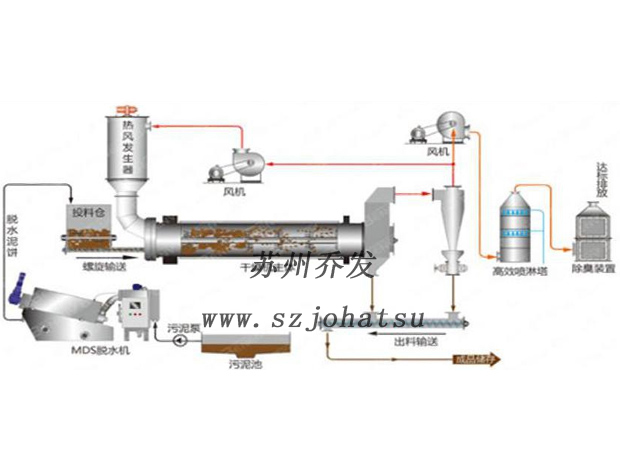

The carbonization system is composed of a quantitative feeder, a rotary cylinder carbonization furnace, a combustion furnace, a combustion blower, a water-cooled heat exchanger, a cyclone dust collector and a chimney.

The carbonization furnace is a horizontal rotary body, which uses indirect heating. The hot blast furnace on its side generates high temperature and heats the rotating furnace body. The materials in the furnace body are heated and decomposed in the state of low oxygen, and a large amount of dry distillation gas is produced. The material is exported from the end of the furnace body through the transfer of the furnace body, and the output end is equipped with the product condensation and collection system, and the product is collected after cooling; The high-temperature flue gas discharged from the combustion is pumped to the dryer for drying the sludge. In terms of tail gas treatment, when the temperature in the combustion furnace reaches more than 800 ° C, the dry distillation gas can be completely burned to achieve harmless treatment, and the exhaust gas is cooled by the water-cooled heat exchanger, and is removed by the cyclone dust collector and discharged into the atmosphere.