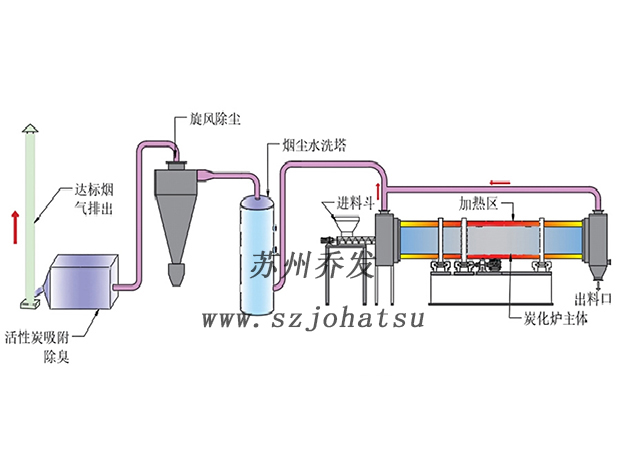

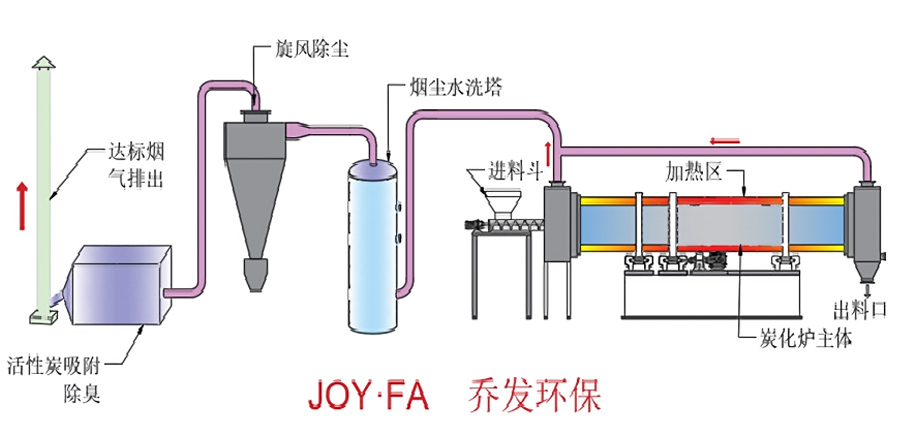

1. The kiln body structure is made of molded steel, the furnace tube is made of high temperature resistant stainless steel SUS316L material as the bearing cylinder, the electric heating is made of silicon carbon rod, and the heat is evenly arranged at the bottom of the kiln, and the heat of the equipment drum is transferred to the material by constant rotation. The furnace is made of light high temperature resistant thermal insulation material.

2. The wet material is sent to the hopper by the belt conveyor or bucket elevator, and is sent to the cylinder body by the cutter feeder. The cutter feeder is designed for frequency conversion control, and the feeding speed is adjusted arbitrarily.

3. Materials pass through the carbonization furnace because there is always a wind tunnel in the circumferential L-shaped shaking plate and the thermal efficiency is low, Qiaofa company designs a curved new lifting plate in the existing carbonization furnace and arranges it in layers and equidistant on the cross-section of the carbonization furnace. The materials entering the carbonization furnace are first brought to a certain height by the circumferential L-shaped poplar plate, and then the backward materials enter the central curved cross-section poplar plate. The material is thrown from the upper L-section lifting board to the L-section lifting board again, thus forming layers of parabolic blanking, extending the residence time of the material in the machine, increasing the opportunity for the exchange of the material and hot air, thus improving the thermal efficiency. At the same time of carbonization, due to the handling of the cylinder, the material is discharged from the end collection device of the carbonization furnace and is transported to the carbonization product storage bin for preservation.