Product introduction

Due to the domestic air pollution situation in recent years, a series of drawbacks of traditional waste incineration has increasingly attracted the attention of the country. In order to adapt to and apply, the carbonization pyrolysis technology of waste has emerged. Through the carbonization pyrolysis of domestic waste, agricultural and forestry waste (rice and wheat husks, sawdust wood chips, various stalks, fruit husks, dead leaves, medicinal residues, sludge, etc.), Finally, the formation of industrial and agricultural resources can be used as heat sources such as carbon particles and organic fertilizers, fully realize the transformation of waste into treasure, and no flue gas and harmful gases are emitted in the carbonization process. Pyrolytic carbonization furnace is the core of waste carbonization equipment, Qiaofa Environmental Protection has developed a number of series, for different materials pyrolysis carbonization.

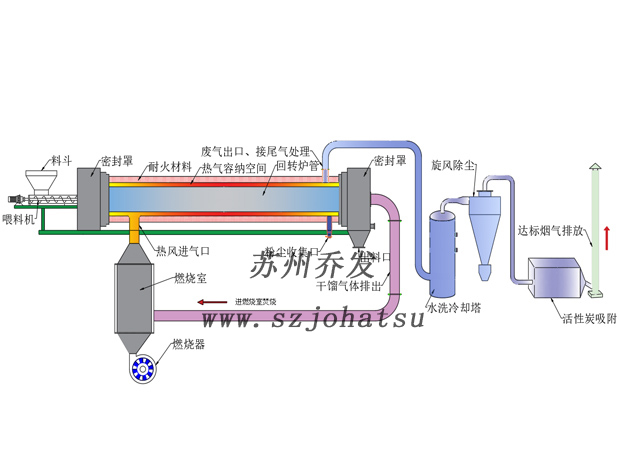

Suzhou Qiaofa Environmental Protection develops the anaerobic pyrolysis and gasification device of medical residue and sludge on the basis of the separation design of pyrolysis chamber and combustion chamber. The waste pyrolysis furnace is the core equipment of waste carbonization. The pyrolysis and carbonization furnace is a horizontal cylinder structure on the whole, adopts indirect heating method, and the heat source is the side hot blast stove burning to produce high temperature. The materials in the pyrolytic carbonization furnace are heated and decomposed under the condition of low oxygen, and the dry distillation gas containing a large amount of carbon monoxide, methane and hydrogen is discharged. After being drawn out by the induced draft fan, the wood tar and wood acetic acid are separated through the flue gas separation device to obtain high-purity combustible gas, which is fully burned into the self-equipped burner to heat the main engine. Thus, most of the flue gas can be self-recycled.

The materials in the pyrolysis furnace are discharged from the end after carbonization and decomposition in the heated furnace (usually controlled at around 800 ° C, the temperature and internal lifting conveyor can achieve carbonization without burning into ash after targeted optimization and adjustment), and the carbonized products are collected through cooling and collection system.

Process flow

Suzhou Qiao Fa environmental protection pyrolysis carbonization furnace equipment continues to introduce domestic and foreign experts and absorb Italy, Japan technology innovation and improvement, complete sets of pyrolysis carbonization furnace system has achieved no pollution and zero emissions. The dried raw materials are transported to the pyrolytic carbonization furnace by conveyor. After spraying, cooling and purification, the flue gas discharged in the process of carbonization is sent to the self-matching burner by the induced draft fan for combustion and heating of the pyrolytic furnace to realize the recovery and utilization of flue gas.