Coordinated disposal of fly as…

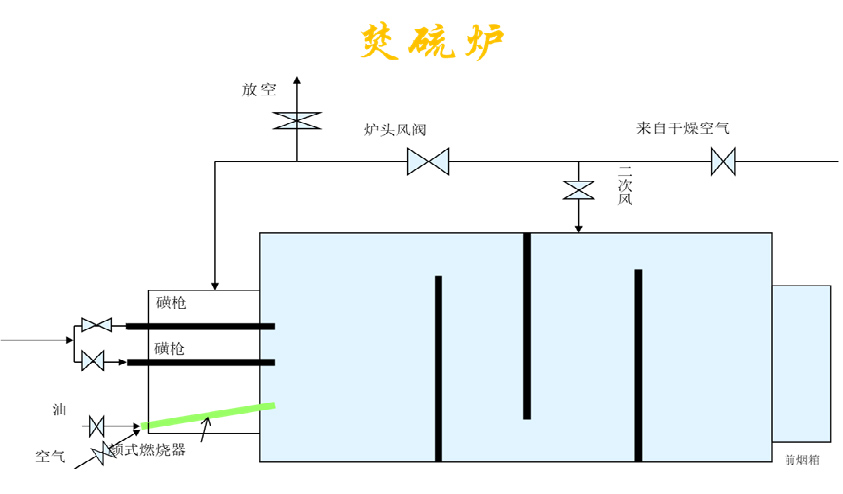

The sulfur burner is of high efficiency horizontal or vertical type with steel cylinder lined with firebrick and insulation brick. In order to make full contact between sulfur and air, three baffle walls are set up in the furnace body. At the same time, in order to avoid insufficient sulfur combustion and the production of elevated sulfur, a secondary air is set up to supplement the air volume and adjust the furnace temperature, so as to promote complete combustion and avoid the production of elevated sulfur. Due to the large load of the equipment, two sulfur nozzles are set up and mechanical atomization is adopted (that is, sulfur atomization by liquid sulfur pressure). In addition to ensuring the required amount of sulfonate, the nozzle design must also be able to form particles that are easy to atomize, the spray Angle is large, the atomization stroke is short and the dispersion is uniform. In order to prevent the spray gun from being damaged by high temperature in the furnace and caused by heat, the sulfonate viscosity rises and causes blockage, the spray gun has a steam jacket.