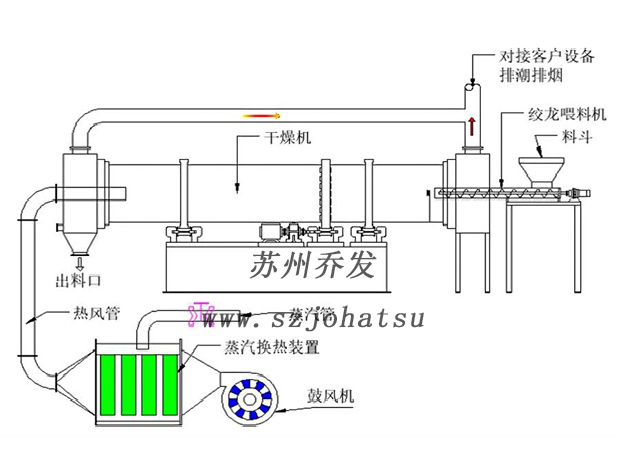

Rotary steam dryer for waste slag

High efficiency and energy saving rotary dryer: the wet material is sent to the hopper by the belt conveyor or bucket elevator, and is sent to the cylinder body by the winch feeder. The winch feeder is designed and controlled by frequency conversion, and the feeding speed is adjusted arbitrarily.

Consult Now