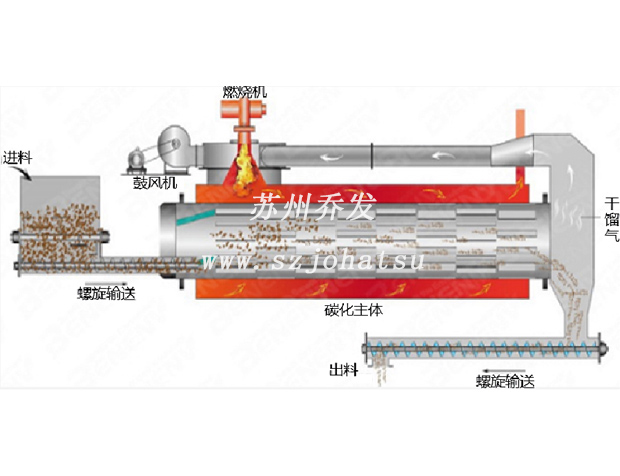

Solid waste, hazardous waste, manganese slag carbonization furnace

The material enters the carbonization furnace, the kiln chamber of the carbonization furnace can be designed in series, the carbonization furnace uses natural gas for indirect heating, and the working temperature of the carbonization furnace is 800℃

Consult Now