Coordinated disposal of fly as…

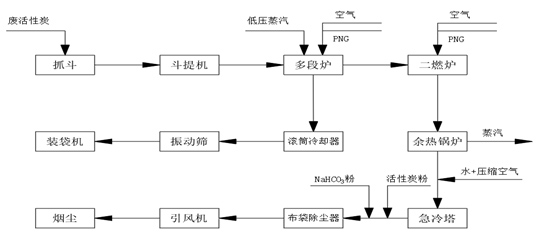

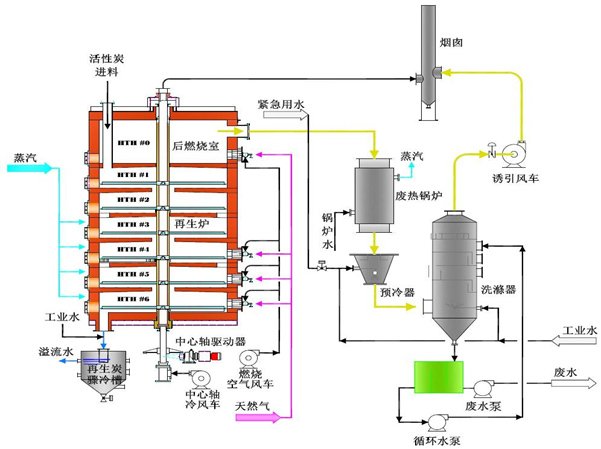

The activated carbon regeneration system mainly adopts multi-stage rake furnace for regeneration, which has the advantages of high recovery rate of activated carbon, small footprint, low operating cost and simple operation of equipment.

The integrated system of activated carbon adsorption, purification and regeneration is mainly used in large-scale water treatment, printing and dyeing, food decolorization and other fields with a large amount of activated carbon. In the process of using activated carbon, the saturated activated carbon is discharged from the bottom of the activated carbon adsorption tower at a fixed time and quantitatively, and then transported to the activated carbon regeneration system (rotary furnace or multi-stage rake furnace) by hydraulic transport; The regenerated activated carbon is hydraulically transported to the activated carbon adsorption tower, and fresh activated carbon is quantitatively supplemented to ensure the stable operation of the activated carbon adsorption system.