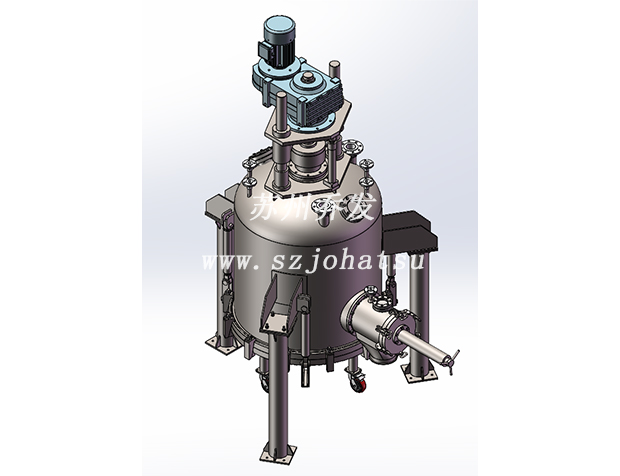

① Can be completed in one machine filtration, washing, drying and other operations, a multi-purpose machine.

② Closed operation, especially suitable for handling flammable, explosive, toxic or highly toxic dangerous products and do not allow pollution of delicious food, biological products and drugs.

(3) From the feed to the product discharge, the whole process is completed in one machine, so that the process is greatly shortened, the number of equipment is greatly reduced, so that the investment in plant and equipment and process pipes, valves, etc., is greatly saved.

④ The special mixing structure, coupled with the hydraulic lifting device, can not only make the mixing device fully and efficiently stir the material, but also save the mixing power.

⑤ Because the machine is equipped with bottom plate filter and cylinder filter, the filtration area is 2-3 times that of conventional equipment, which greatly reduces the filtration time and improves the filtration efficiency.

In the washing stage, because the function repeatedly automatic mixing and pulp washing, washing convenient, washing effect is good.

⑦ Because of the jacket of the cylinder, under the filter plate or the hollow mixing shaft, the mixing slurry can heat and dry the material, and the drying efficiency is high. The material can also be dried by hot air, which greatly reduces the drying time.

Because it is fully closed operation, there is no pollution to the material, so the processed products are of high quality and the operating environment is excellent.