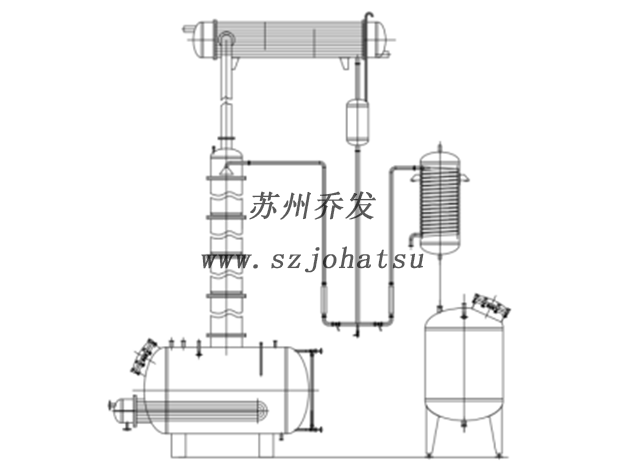

Rectifying tower

Distillation column is a kind of tower-type gas-liquid contact device for distillation, and it is also a kind of mass and heat transfer device widely used in petrochemical production. High purity products are often required in petrochemical production, which can be obtained by distillation process.

Consult Now