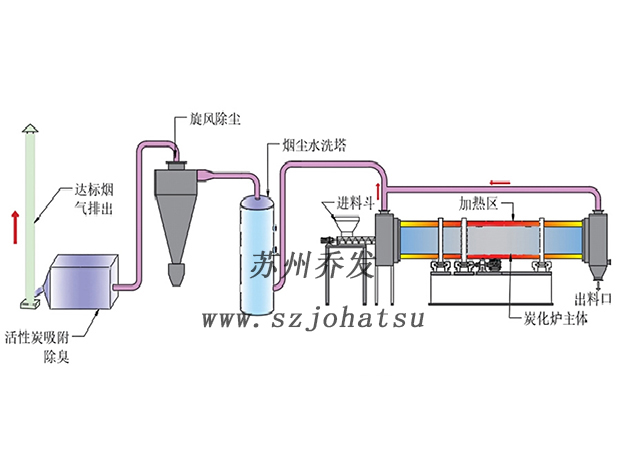

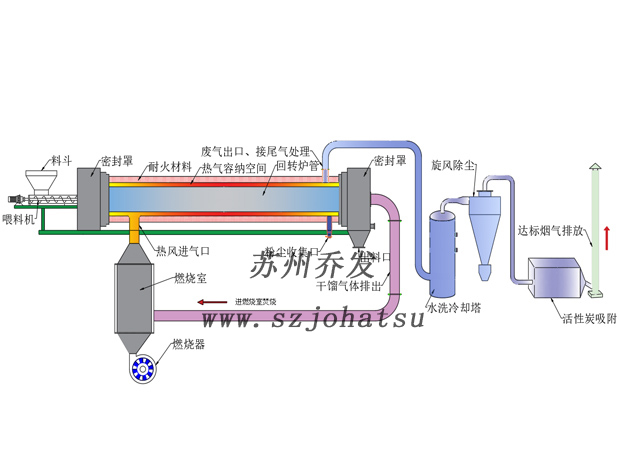

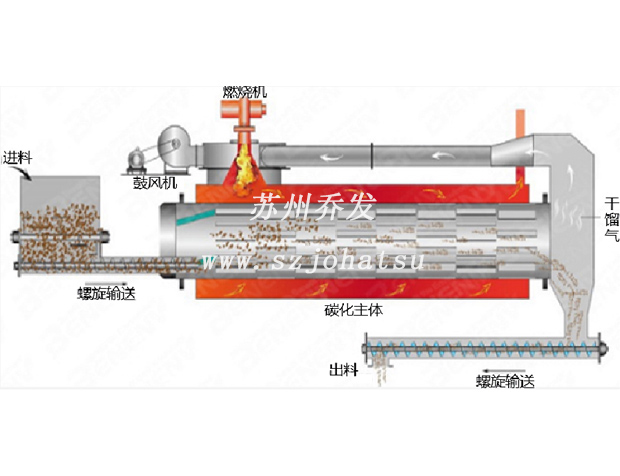

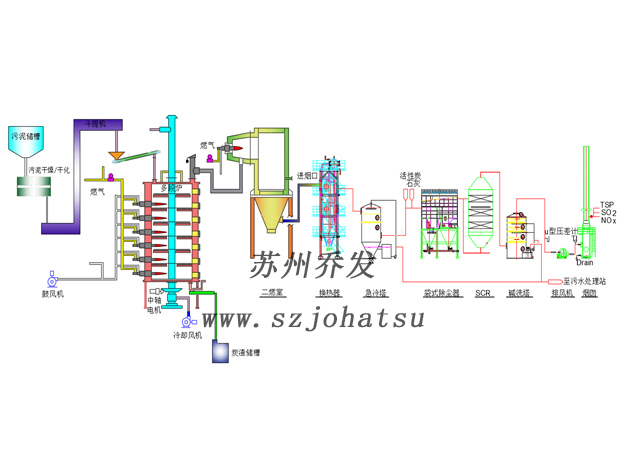

Sludge rotary continuous charring furnace

The carbonization system is composed of a quantitative feeder, a rotary cylinder carbonization furnace, a combustion furnace, a combustion blower, a water-cooled heat exchanger, a cyclone dust collector and a chimney.

MORE>>